I have had a few people ask about the Older Miller Syncrowave 350LX Units making a Timer / Sequencer.

These Units Came with a Pulse Board Standard, they Did Not Come with a Timer / Sequencer Board it was a Option.

The miller pulser and timer / sequencer boards I have made will not work on the 1st 350LX version uses 183101/183105 and the Wiring is Different and the layout is also, most notably the rotary selector switch on the timer. So, Unless I can find a Name Plate Miller Part # 183260 or someone local so can pull the measurements off of and someone local that is willing to let me test the boards on it is Not Going to Happen any time soon.

(01/2026 I have a 183105 Board In My Hands)

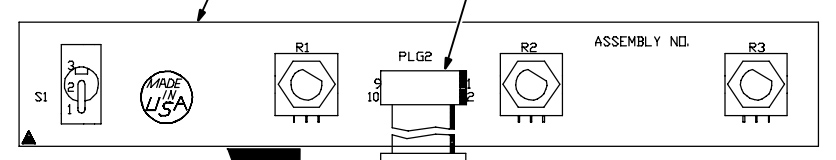

The 2nd Version of the 350LX uses the Same Miller 300547/300548 boards which my replacement boards will work on.

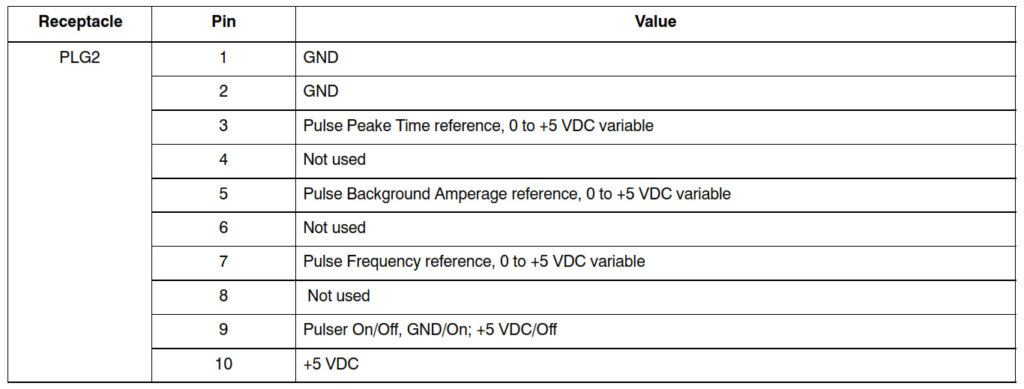

Miller Part # 183101 Pulser (This Board Was Standard on all the 350LX Units)

I will not be making a replacement for this board at this time I have had zero demand for one.

Miller Part # 183105 Timer / Sequencer Info.

I found this one on feebay here https://www.ebay.com/itm/305495770911 if anyone is willing to send me one to pull the measurements and data of the switch I am willing to do so. (Do Not Need this any More)

I Obtained one New in The Box cost me a pretty penny.. What I have to do Just to get some measurements!

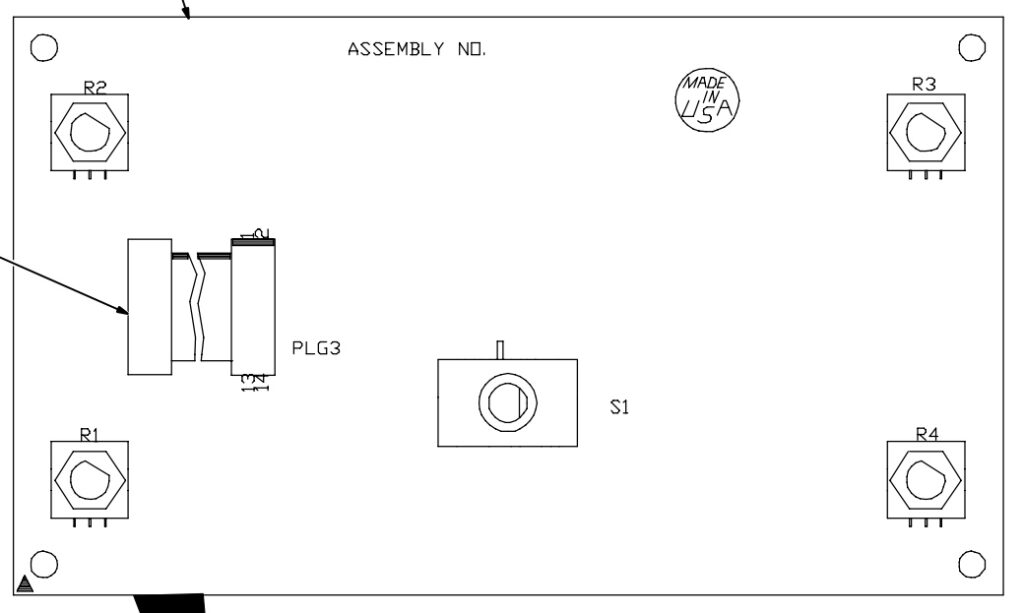

Board did not Fit Fully on the X-ray machines Sensor had to do 2 shots, Yea I know an X-ray was not required but took one for the fun of it.

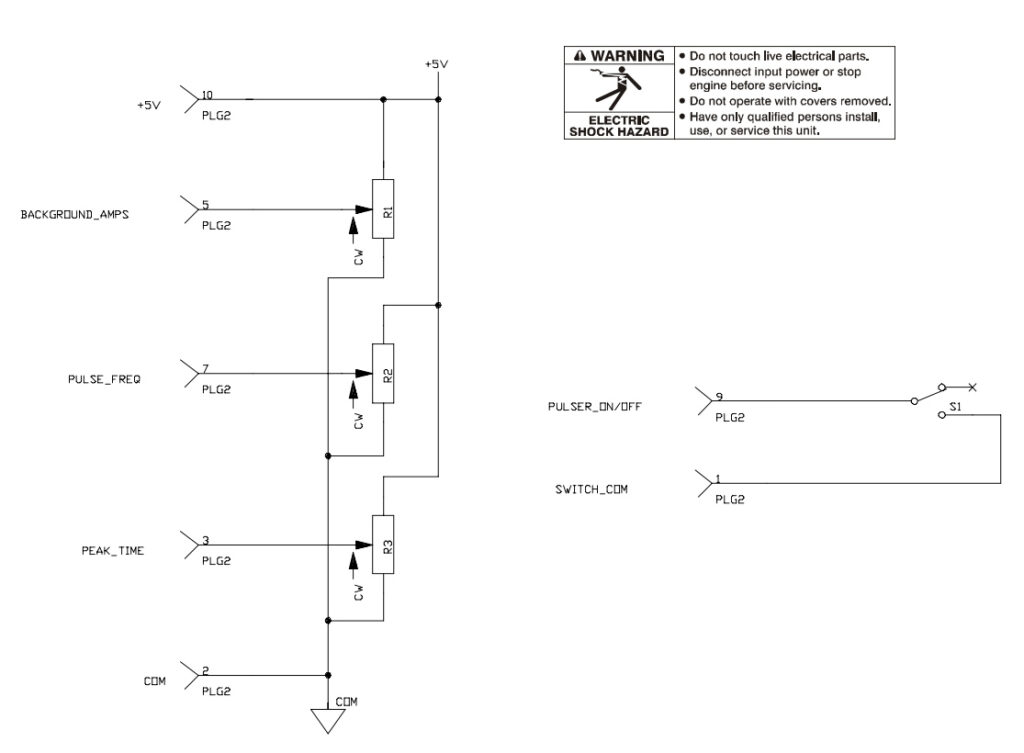

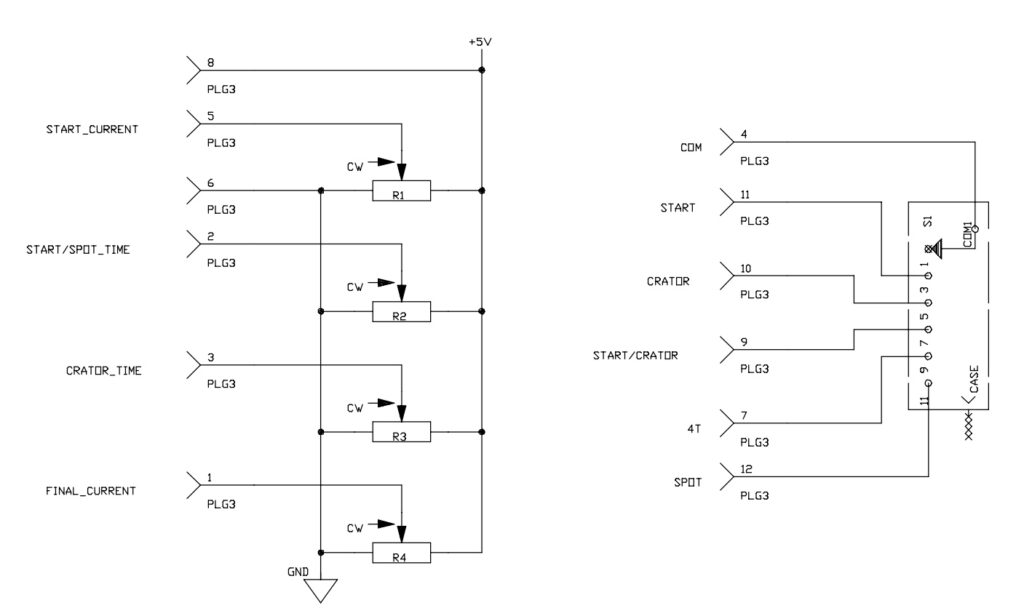

Yes, you Can DIY your approach by utilizing this information to craft a pulser and/or timer sequencer Dead Bug style. However, enhance your awareness when engaging in a Dead Bug build, as the welder generates high frequencies. To ensure optimal performance by employing the use of high-quality copper wire and keeping them as short as possible. Avoid the use of wire-wound potentiometers opt for Palstic-carbon and cermet unless shielded internally to prevent erratic / unwanted operation. The challenge lies in identifying a suitable rotary switch to complete your Dead Bug style masterpiece.

Have Fun!!

If I can source a front plate or a local with a 350LX that I can get the Measurements form and to the test fitting of 3d printed model I will make a sequencer for the Legacy 350LX.

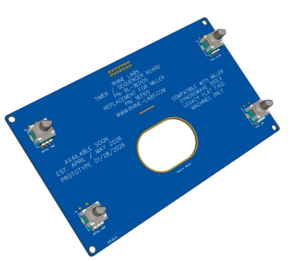

01/20/2026 I will be making progress on this model in the next couple weeks… stay tuned! Since these came with Pulser Boards as standard i will only be doing a Sequencer / Timer Board only to replace the Miller 183105.

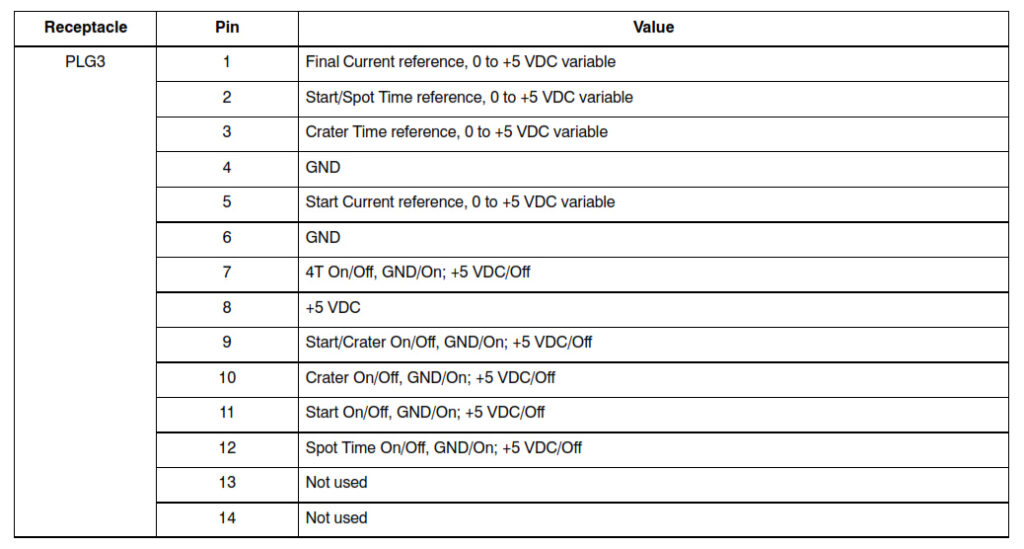

01/28/2026 I received my Board to get the Measurements For the Pot Spacing and Proper Switch Pin Out… I have left out the Switch on this rendering, The actual Prototype will have a switch fitted to a separate board. Once the sample switches arrive I will know my path to take but i am thinking it bay be a stand alone switch like I did with the button on the Pulser Boards as it will be mechanical item and may eventually need to be replaced and to ease servicing be able to do it without removal if the board.

Backup is the Removable Switch.

I am 3D printing the Front panel Holes Matching the Original Board potentiometer and switch spacing. Nice thing about EASY EDA Pro is that you can Drop hole in place of your potentiometers and switches export to 3d step and Print no text would be cool. I could always add something in the slicer.

About 40min later We have a Pattern to test fit. All Looks good not to do none with the slightly larger holes for the potentiometers I will be using.

Perfect fit drops right on… need to work on the holes on the coroner but prob not required.

Fits little Snug on top left the potentiometer there is not 100% centered but acceptable. This one will be my assembly template go guage as the knob shafts on the potentiometers I use are 6mm and the holes here are 6.5mm. The potentiometers I use have a bushing size of 6.7x5mm. the Holes in the pannel are about 7mm to 7.10mm if I recall so very little tolerance for assembly error.

Next is final fit and 3D print the Model and see how it fits the panel template.

I am going to try and have this be no modification to the welders panel one may have to open the selector switch hole a little bit we shall see when my sample rotary switches arrive. In the spirit of future repairability I only want to use standard off the shelf parts nothing custom made but it may be unavoidable. Having to open a hole for the switch is s small modification.

I will be accepting pre-orders est middle of February/March. You can e-mail 350lxpe @ rhine-labs.com with your name address and phone when I have the Rev 1 boards ordered I will send out invoices to people on the list first.

Modern Miller 250DX/350LX Pulser and Sequencer Project

Legacy Miller 250DX Pulser and Sequencer Project

Last Updated on January 29, 2026 by Steven Rhine